How To Repair Engine Block Threads

Strippers can be expensive. Finish thinking rap stars, lap dances and sports celebrities. We are talking nigh a "stripper" in terms of a pigsty that has had its threads stripped out or damaged. In addition to being expensive to repair, strippers as well require a swell deal of time and normally evoke a great deal of frustration. Fortunately, understanding the history of the materials beingness threaded along with the science of inserts can help you lot avoid encountering a stripper or, at least, be prepared to select the correct parts to repair a stripper. Done correct, you'll never accept a thread failure in the same hole once more.

Text and Photos by Michael Ferrara // Illustrations by Paul Laguette

DSPORT Upshot #166

Hard Times

Forty years ago, the world was a harder place. Your grandparents weren't lying to you. Cast-iron alloys and steels were the bones building blocks for just almost anything. On the automotive side, grayness cast iron was the "go-to" material for engine blocks, cylinder heads, manifolds, housings and heavy brackets. Steel was the material of choice for smaller brackets, fasteners and the frame and torso of the vehicle. While the mechanical backdrop (forcefulness, stiffness, impact and corrosion resistance) varies immensely across different grey cast iron and steel alloys, they all have one thing in common. For the most part, these materials, when used on components that have threaded holes, are all on the "hard" side with Brinell Hardness ratings (HB) in the 150 to 300 range (tool steels can become up to 900 on this scale). Being hard in nature, grey cast iron and steel will tend to have exceptional thread strength and thread retentivity capabilities as long every bit these materials are protected from corrosion. When thread damage does occur in bandage iron and steel, the most mutual practise is to drill out the existing threads and tap the hole to have a larger fastener. In many cases, this solves the problem. When the same size fastener must exist used, an insert tin be installed to save the twenty-four hour period.

Going Soft

Today, it's non merely "emo" millennials that are softer. Nosotros alive in a softer world. The materials that have replaced grey cast iron and steel are relatively so . The world has moved from the Steel Age to the Aluminum Historic period. Pure aluminum will only hit fifteen on the HB scale, whereas aluminum alloys tin can range in hardness from twenty-to-150. The aluminum alloys used on most of the sand cast components in a vehicle are typically in the 45-to-65 range in terms of hardness. The highest hardness cast-aluminum alloys are used in block and cylinder heads. These will typically have a range of hardness from 75-to-85, about the same as 6061-T6. Just 7075-T6 aluminum alloy has a hardness of 150 which is on par with grayness cast iron.

Hard Commodities Meets Soft Threads

While the materials where threads live have become softer, the materials used for fasteners have in many cases become harder. In fact, some of the super-alloys used in high-operation head studs and rod bolts have hardness levels approaching that of tap (every effort to drill out a broken tap?). As a consequence, information technology's no surprise that strippers are more mutual than ever before. Since most of the threads on today's vehicles are made of materials with only one-third to one-half the hardness of grey cast fe, it's no wonder that more threaded holes experience thread damage than e'er before. It's been said, "If a threaded hole in a softer metal uses a fastener that is installed and removed on a regular basis, a harder-textile insert is a must." Unfortunately, the price and time involved with installing inserts at an OEM level means that it will never happen on a big scale. There may exist a few cardinal, high-stress locations in an engine cake or suspension component, simply 99 percent of all the threaded holes will non come from the factory reinforced with an insert.

The Solution

If every single aluminum component in the world could be manufactured from 7075-T6 aluminum alloy (which has equal hardness to typical grey cast fe alloys), the number of strippers in the world could be brought back down to the Steel Age numbers. Due to the high-cost of this fabric and the need to bandage sure parts, this will never happen. Instead, the solution for stripped threads are inserts.

Insert Tech 101

Thread-repair inserts come up in a multifariousness of materials and in a myriad of designs from domestic and overseas manufacturers. Timed thread body inserts, wire whorl inserts and keyed inserted make up the three major families of thread inserts you lot'll likely encounter. Each design has its claim and may be superior to another based on budget, installation time, maximum O.D. permitted and the necessary strength of the repair or upgrade. And so which blazon of insert is all-time? Information technology all depends on the grading criteria and the application. Here'south an overview of the three main types in lodge of popularity.

HeliCoil Helical Coiled Wire Inserts

Rough-and-tumble is a brand synonymous with bandages, while Heli-Ringlet is a brand synonymous with thread repair inserts. Come across a stripper and the solution is often touted as ,"just HeliCoil it." HeliCoil and the like designs inspired past this pattern are available from a number of other companies. Information technology's the thread-repair solution most likely to exist establish at local car parts stores. HeliCoils were originally made from foursquare, stainless-steel wire wound so that the wire had a diamond contour that would fit into the repair threads. When installed into the larger repair threads, the wire forms a set of threads engineered to meet the original dimension of the stripped-out hole. The repair threads for the HeliCoil insert are made by using a Spiral Thread Insert or S.T.I. tap. This is the aforementioned type of tap used for some other inserts. An S.T.I. tap uses a simple but somewhat misleading naming convention. An S.T.I. tap is actually virtually 14 percent larger in bore than a standard tap of the same designation (M10x1.25 versus M10x1.25-Due south.T.I.).  Here'southward how it works for an M10x1.25 thread repair. Starting time, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). And so you lot would utilise an M10x1.25-S.T.I. tap. This Southward.T.I. version of the tap will have a major bore of upward to xi.787mm, whereas a standard M10x1.25 tap is about i.5mm less in bore. Once the hole has been drilled, tapped and cleaned for the repair insert, the HeliCoil insert is screwed into place with the installation tool. Once the insert is located in the general vicinity of the desired location, the tab is broken off to secure the insert in place. In addition to being the most pop and readily available thread insert, HeliCoils too require the minimum amount of oversizing to the pigsty (same every bit TIME-SERT), provide a corrosion resistant thread material, and deliver the least expensive solution (nearly the one-half the price per insert compared to TIME-SERT and just one-5th to ane-20-fifth the price of Keenserts). On non-blind, through-holes, HeliCoils can too be installed from the backside of the hole making it the only solution in some situations. [tabular array id=i /] While HeliCoils may exist 1 of the better choices for repairs that are not under extreme stress, strains and vibrations, it does take its shortcomings. First, since the insert is not a single continuous piece, installation can sometimes exist slightly challenging compared to solid-body inserts. In addition, the discontinuous nature of the insert means that using an anaerobic thread locker ways that both the insert and the fastener screwed into the insert are both going to get the thread locking compound whether that's your intention or not. When a repair is beingness made on the vehicle, special attention must also be exercised to ensure that the locking tang doesn't become a foreign object that falls into a critical expanse. Finally, the strength of a HeliCoil repair has been demonstrated to be less than a solid body insert. We hope to exam a number of unlike thread repair insert designs in the future to give this a more definite number.

Here'southward how it works for an M10x1.25 thread repair. Starting time, you would drill the hole with a 10.25mm drill (a standard M10x1.25 thread would use a much smaller 8.75mm drill). And so you lot would utilise an M10x1.25-S.T.I. tap. This Southward.T.I. version of the tap will have a major bore of upward to xi.787mm, whereas a standard M10x1.25 tap is about i.5mm less in bore. Once the hole has been drilled, tapped and cleaned for the repair insert, the HeliCoil insert is screwed into place with the installation tool. Once the insert is located in the general vicinity of the desired location, the tab is broken off to secure the insert in place. In addition to being the most pop and readily available thread insert, HeliCoils too require the minimum amount of oversizing to the pigsty (same every bit TIME-SERT), provide a corrosion resistant thread material, and deliver the least expensive solution (nearly the one-half the price per insert compared to TIME-SERT and just one-5th to ane-20-fifth the price of Keenserts). On non-blind, through-holes, HeliCoils can too be installed from the backside of the hole making it the only solution in some situations. [tabular array id=i /] While HeliCoils may exist 1 of the better choices for repairs that are not under extreme stress, strains and vibrations, it does take its shortcomings. First, since the insert is not a single continuous piece, installation can sometimes exist slightly challenging compared to solid-body inserts. In addition, the discontinuous nature of the insert means that using an anaerobic thread locker ways that both the insert and the fastener screwed into the insert are both going to get the thread locking compound whether that's your intention or not. When a repair is beingness made on the vehicle, special attention must also be exercised to ensure that the locking tang doesn't become a foreign object that falls into a critical expanse. Finally, the strength of a HeliCoil repair has been demonstrated to be less than a solid body insert. We hope to exam a number of unlike thread repair insert designs in the future to give this a more definite number.

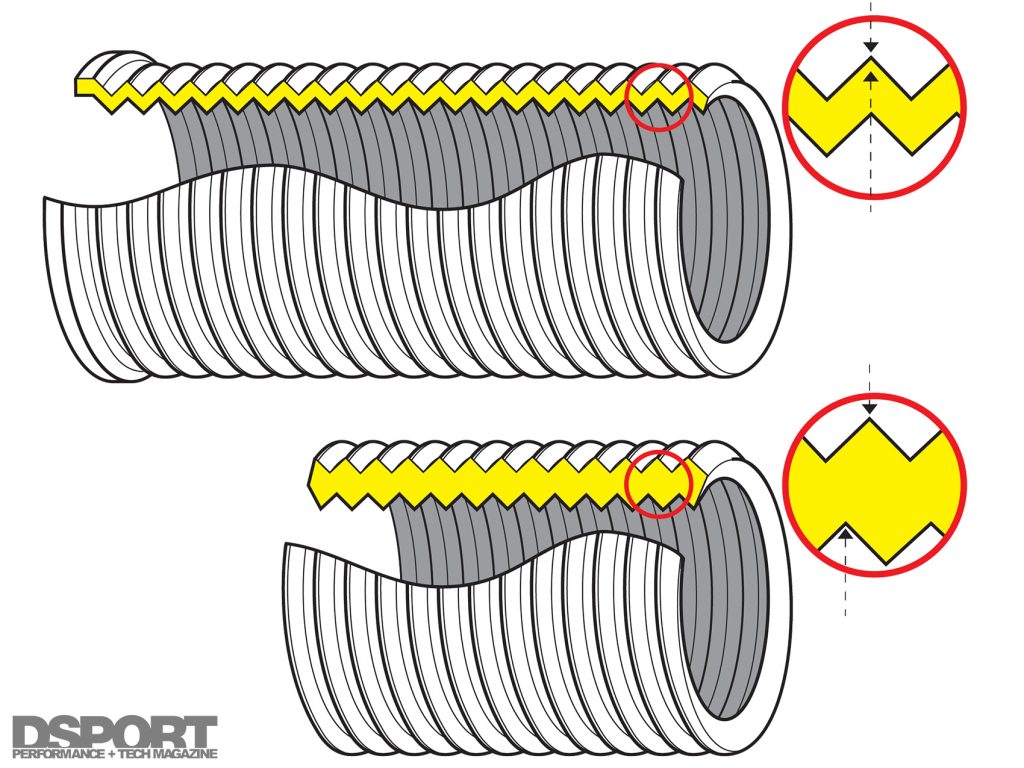

This illustration displays the deviation between TIME-SERT inserts which sync the outside and inside threads with each other versus Keenserts that do not sync outer and inner threads, which leads to inconsistent wall thickness and the demand for a larger O.D. sizing of the insert.

Time-SERT Timed Solid Body Insert

While non every bit well known to the mainstream, Fourth dimension-SERT and the family of solid torso inserts are many mechanics number one choice for thread repairs in high-preload fastener applications. This solid torso thread repair solution uses a solid carbon steel or stainless-steel continuous insert that has the outside and inside threads in sync or (in time) with each other. By keeping the threads lined up on the inside and outside of the insert, the cross-exclusive-surface area or wall thickness can remain consistent. The result is the ability to maximize strength for a given exterior diameter of insert.  TIME-SERTs employ the aforementioned drill and tap requirements as HeliCoils, equally both apply Southward.T.I. taps. Installation is similar, but there are a few key differences due to the difference in design. First, TIME-SERTs use an oversized locating flange on the peak end of the insert. Hence a combination drill/counter-irksome tool or a drill and divide counterbore must be used. This flange allows the thread to be repeatably located or positioned at a specific location (something that cannot be accomplished with a HeliCoil or Keenserts). 2d, there is no tang for locking. Fourth dimension-SERTs use a special tool to lock the lesser threads into the threaded repair hole. Since Time-SERTs are a solid torso, thread locking compounds tin can be used on the inserts outer threads for boosted strength without it affecting the inside threads and fastener. While Time-SERTs offer advantages over other thread repair insert designs, it also has a few drawbacks. Beginning, it's about twice the cost of a HeliCoil per insert. Second, it must be installed directionally, equally its flanged-design requires the non-flanged side to be threaded in start. On through holes, information technology can exist used by installing it from either side. On blind holes that are not deep plenty to provide enough room for threads and the flange, the flange side can be milled or filed off al after. Yet, if there were just one design of insert that we'd have admission to for all thread repairs, nosotros'd probably select TIME-SERTs. TIME-SERTs deliver the highest strength with the least corporeality of intrusiveness with regard to the size of the repair threads versus the original threads.

TIME-SERTs employ the aforementioned drill and tap requirements as HeliCoils, equally both apply Southward.T.I. taps. Installation is similar, but there are a few key differences due to the difference in design. First, TIME-SERTs use an oversized locating flange on the peak end of the insert. Hence a combination drill/counter-irksome tool or a drill and divide counterbore must be used. This flange allows the thread to be repeatably located or positioned at a specific location (something that cannot be accomplished with a HeliCoil or Keenserts). 2d, there is no tang for locking. Fourth dimension-SERTs use a special tool to lock the lesser threads into the threaded repair hole. Since Time-SERTs are a solid torso, thread locking compounds tin can be used on the inserts outer threads for boosted strength without it affecting the inside threads and fastener. While Time-SERTs offer advantages over other thread repair insert designs, it also has a few drawbacks. Beginning, it's about twice the cost of a HeliCoil per insert. Second, it must be installed directionally, equally its flanged-design requires the non-flanged side to be threaded in start. On through holes, information technology can exist used by installing it from either side. On blind holes that are not deep plenty to provide enough room for threads and the flange, the flange side can be milled or filed off al after. Yet, if there were just one design of insert that we'd have admission to for all thread repairs, nosotros'd probably select TIME-SERTs. TIME-SERTs deliver the highest strength with the least corporeality of intrusiveness with regard to the size of the repair threads versus the original threads.

Once the hole has been drilled and tapped with the Due south.T.I. tap, i) the TIME-SERT installation tool gets a drop of oil before ii) the Fourth dimension- SERT is threaded onto the tool. 3) Threadlocker can be applied on the outer threads and 4) inserted into the hole to be repaired. When the insert's flange bottoms out 5) information technology as well locks the bottom threads in place. vi) Remove the insert tool and the vii) TIME-SERT repaired hole is ready.

Keenserts Keyed Threaded Body Repair Inserts

Keenserts are very thick-walled, solid body thread repair inserts with retaining keys. While a Keensert looks to be very similar in design to a TIME-SERT, there are major differences. While both are solid torso designs that are flanged (requiring counterboring for installation), Keenserts exercise not have the inner and outer threads "timed" with each other. In fact, a Keensert may take an outer thread with an entirely different thread pitch than the inner. Unlike thread-repair inserts that require South.T.I. taps, Keenserts use standard taps that are two steps larger than the original threaded hole. This means that an M14x1.5 tap would be used for a M10x1.25 thread repair insert. As such, the corporeality of textile that must be drilled out and the size of the tap are both considerably larger than what is required for a HeliCoil or Time-SERT repair.

To retain the insert, Fourth dimension- SERTs use a flange up top and a swedged fit at bottom, while Keenserts use two or four stakes.

For an M10x1.25 thread repair with a Keensert, a 12.5mm drill would be used for the M14x1.five tap. The M14x1.5 tap would have a major bore upward to 14.4mm (an M10 repair with an S.T.I. tap would merely take a 11.787mm major diameter). That's a much bigger hole which can exist beneficial in some application where severe corrosion is prevalent in the original threads. The Keensert would then exist threaded into the drilled, tapped and cleaned hole with the Keensert installation tool. Thread locking compounds tin be used due to its solid torso blueprint. Once set in position, the installation tool is then used to drive in the 4 primal stakes into position. This provides the ultimate mechanical locking of the insert in place. Hence, this design sports infrequent resistance to vibration. Now the downside. The massive exterior diameter of the insert makes information technology unviable in applications where the material around the original threaded pigsty is limited, such every bit any "thin-wall" castings. Second, the cost for a standard-steel Keensert is about 4.five times that of a HeliCoil and more than than double the cost of a Time-SERT. If you want a stainless-steel Keensert, the price goes through the roof being about 25 times the cost of a HeliCoil.

BIG-SERT Thread Repair Insert

For applications that will benefit from a large-diameter insert or when yous are replacing a standard TIME-SERT, Time-SERT offers a line of oversized BIG-SERTs that are thicker wall and use an oversized Due south.T.I. tap. For example, an M12x1.25 S.T.I. tap would be used on an M10x1.25 BIG-SERT insert.

Big, Bigger, Biggest! Here is a comparison of a standard (left) M12x1.five tap, a M12x1.5 S.T.I. tap (center) for Time-SERT and HeliCoil inserts and a M16 tap for Keenserts (correct).

The Bottom Line

HeliCoil, TIME-SERT, Keensert or BIG-SERT? We've had the opportunity to apply all three designs in real-world conditions. So which type of insert is best? The reality is that information technology all depends on the application and quality of the installation. We've never had whatsoever of these inserts neglect on us. Are nosotros lucky? Non actually. Simply having the knowledge of the strengths and limitations of each blueprint volition let you to select the correct insert for the job. If you are not sure, call the manufacturer and ask.

The TIME-SERT Universal Head Bolt Thread Repair Kit (for first time repairs) come up with fixture plate, alignment tool, a drill/counterbore bit, tap, installation driver, metal rule, end collar, lube, threadlocker and more.

Keenserts: Keyed threaded torso insert

+ Thick-wall design delivers highest strength for a given commodities diameter + Uses conventional, easy-to-source taps + Solid design provides easy installation + Solid design allows use of thread locking sealer on outer threads + Flanged design allows for positive location of the threads into the object + Positive locking pattern with four key stakes provides maximum vibration resistance – Makes the largest hole and requires largest tap diameter versus last bolt diameter – Over 5x toll of HeliCoil, Over 2x price of Time-SERT – Availability: Hardest to source, limited distributorsTIME-SERT: Timed threaded torso insert

+ Thin-wall design delivers highest strength for a given repair-tap diameter + Smaller hole and tap requirements than "keyed" style insert + Solid design provides piece of cake installation + Solid design allows use of thread locking sealer on outer threads + No weak spots…consistent wall thickness due to "timed" design + Flanged design allows for positive location of the threads into the object + Self-locking design – Higher price than coiled thread inserts – Availability: Not available at most automotive retailers – Uses harder-to-source South.T.I.-sized tapsHeliCoil: Helical Coiled Thread Repair Inserts

+ Helical coiled wire design results in smaller pigsty and tap requirements than "keyed" way insert + Most readily available thread repair solution + Lowest cost thread repair solution + Can install from behind on through holes – Cannot use thread locking compounds on coiled insert without affecting inner threads besides – Uses harder-to-source Due south.T.I.-sized taps – Tangs tin can become FOD – Simply held in by friction

Source: https://dsportmag.com/the-tech/three-ways-to-fix-damaged-threads/

Posted by: moodytheregoth.blogspot.com

0 Response to "How To Repair Engine Block Threads"

Post a Comment