How To Remove Rear Springs

The rear suspension under some classic Chevys is supported by a pair of leaf springs fabricated up of multiple leaves (strips) of leap steel. Typically, they will have 3 or four private leaves that make a ready of springs. Foliage springs take a specific curvature when they come up from the manufacturing plant, and this curvature and the number of leafs in the leap pack, determines the load capacity and the ride height of the vehicle. We're going to testify you the the procedure and tools required to supplant the foliage springs under your automobile. This is not a hard task, simply take your time and pay attention to what y'all're doing. Besides, information technology's recommended to piece of work on ane side of the car at a time so you accept the other side to refer to if you go stuck.

Tools Y'all Will Need

Unless your suspension is infected with a lot of rust, you shouldn't demand any special tools to complete the job. Y'all will need a couple of sockets (9/sixteen through 3/4-inch), a ratchet, and possibly an extension or two. Also, brand sure you have some wrenches (the same size as the sockets), and a hammer. Lastly, you'll also demand a flooring jack and a few jack stands.

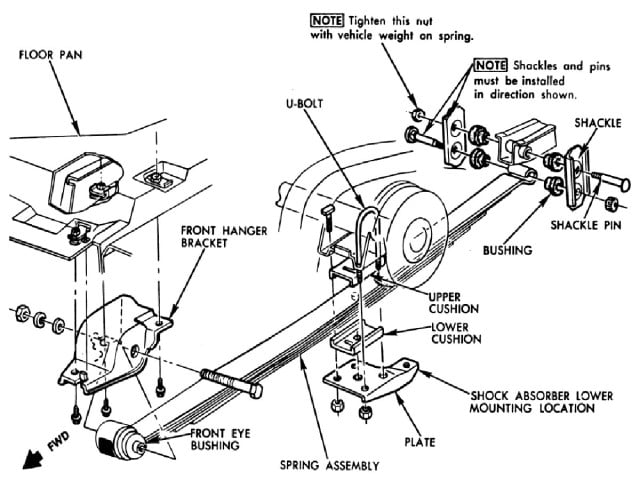

Employ this exploded diagram to follow along with the text as we draw the process.

Step 1: Raise The Rear

Before yous starting time, park your car on a level surface. Place a tire brimming in forepart of, and behind, 1 of the forepart tires to keep the car from moving. Place your floor jack under the differential, and jack upwards the machine high enough and then the tires remain off the ground when the car is supported past placing the jack stands under the frame.

With the machine in the air, place one jack stand nether the frame rail in front of the leaf leap on each side of the car. Side by side, advisedly lower the jack until the auto is supported past the jack stands, and the rear is hanging by the leaf springs.

Proper placement of the jack stands on the frame rail.

Pace ii: Remove The Shocks

With the motorcar supported past the jack stands, identify the jack under the differential, and raise it simply plenty to relieve some of the hanging tension in the springs. Using a socket, remove the ii upper shock-mounting bolts.

You'll demand a socket to remove the daze bolts.

Next, remove the nut securing the shock to the lower mount. Lower the jack enough to remove the stupor from the auto, but don't lower it all the style. This keeps the axle housing from falling while you're doing the work.

Step iii: Remove The Foliage Bound Subclass And Parking Restriction Cable

Got a classic Chevy truck? This is what the front bracket looks like on a '54 Chevy pickup.

Remove the front portion of the leafage jump. On older vehicles, such equally the '54 Chevy pickup pictured above, this is a matter of removing the bolt securing the spring to the bracket. On cars, such as the 1970 through 1981 Camaro pictured below, y'all must remove the 3 bolts securing the jump pocket/forepart subclass to the frame before getting at the nut and bolt that secures the front end of the spring to the car.

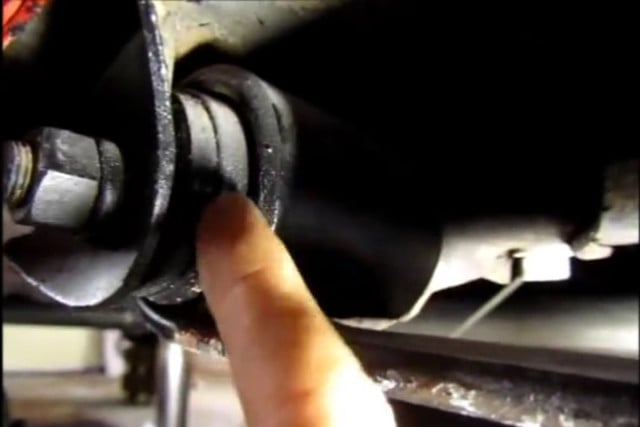

This is the front foliage leap pocket on 1970 through 1981 Camaro. In that location are iii bolts here to remove. Hither we're pointing at the commodities that needs to exist removed to lower the leafage spring from the bracket.

Sometimes, the parking brake cablevision is fastened by a clip, which is usually located near the spring plate on the leaf spring. Remove the cablevision from the clip.

Stride 4: Remove Lower Spring Plate

At that place are four nuts that secure the spring plate to the beam.

Next, remove the four basics from the U-bolts on the lower spring plate. Sometimes, in that location are upper and lower rubber pads between the spring and mounting plate. If they're present, be certain to put them back during reassembly.

A little rut from a torch will aid loosen rusty nuts and bolts.

Before you try to remove the U-bolt nuts, information technology is a good idea to spray a penetrating oil on the threads and then the nuts do not strip the the threads of the U-bolts as you try to remove them. Strip the threads, and you lot'll need to buy new U-bolts.

Left: If your car is equipped with a rear sway bar, you tin use it to help hold the rearend stable. Right: With the iv U-bolt basics removed, you can remove the lower plate/shock mount and rubber pads.

Stride 5: Remove The Rear Shackles And The Leaf Spring

The bolts for the rear shackles insert from contrary sides. Brand note of what goes where for reassembly.

Hither's where having a 2nd floor jack can exist handy. Place the second jack under the foliage spring, and heighten the jack just plenty to contact the spring to relieve some of the tension. Side by side, remove the lower shackle bolt, lower the jack, and remove the leap.

Step 6: Out With The Old

The upper shackle bolt is the concluding one to come out. Remember which side the nut is on.

When you remove the shackles, pay attending to the orientation of the upper shackle bolt. It must go back in the same way it came out. This is so the moving suspension tightens the bolt instead of loosening it. Remove the shackle bushings from the frame so they can be replaced.

Step seven: Adhere The Front Bracket

Brand certain the spring lies flush with the lower edge of the front spring pocket/bracket.

Earlier reassembly, apply antiseize to the new bushings and insert them into the front end spring eye. Likewise utilize anti-seize to the inside of the spring eye. Don't forget to install the tubular bushing support before bolting the leap into the forepart leap bracket/pocket.

Polyurethane versus Safe Bushings:

Hot rodders have been arguing for decades nearly whether polyurethane is amend than rubber for bushings. If you're building a restored show car, or y'all desire more of a stock feel to the ride, you lot desire rubber. Most manufacturers used rubber for their bushings considering prophylactic supports a soft ride quality, and are the main characteristic that influence many hot rodders to use polyurethane bushings. Poly lasts longer, and it's firmer. This is important for functioning enthusiasts.

Position the leap mounting-subclass over the front jump heart of the new spring, and install the bolt through the mounting bracket and jump eye. Brand sure the bolt head is positioned so that it is facing the eye of the car when the jump is installed. This is done in case the bolt loosens, to ensure that while the commodities might get loose, it won't fall out and cause a serious accident.

Stride eight: Install Shackle Bushings

Now is a practiced fourth dimension to replace the shackle bushings located in the frame (at the rear of the spring). Shackle bushings that don't want to come out hands tin be drilled or chiseled out. Be careful to not score the sides of the hole where they are installed.

Polyurethane bushings don't distort over time the fashion rubber bushings do.

Clean the bushing holes prior to installing the new bushings with a trivial WD-forty. Next, apply some anti-seize to both the bushings and the inner bore of the bushing hole in the frame, and slide the new bushings in identify. Don't forget the bushing insert sleeve in the bushing's pigsty. Again, when reinstalling the bolts, make sure the positioning of the bolts is equally they came out. This does quite oft brand information technology a pain to go the commodities in and out, just isn't something that tin be disregarded. Exercise not go frustrated and make up one's mind that installing the commodities is taking likewise long or is likewise hard and only install the commodities however information technology is easiest. It's put together this style for a expert reason. If the bolt loosens and comes out while driving because it is not installed properly, you lot run the run a risk of equipment failure, and possibly, an blow.

Yous may need to employ a pry bar to install the frame bushings.

Anti-seize chemical compound helps make installing the new bushings much easier.

Step nine: Install Shackle

Make sure you insert the shackle-to-spring bolt in the proper orientation.

Next, identify the bushing into the rear spring heart and mount the shackle. Install the through-bolt with the bolt head facing the outside of the car. Raise the rear section of the foliage leap into place, and insert the upper shackle bolt in the proper direction. Leave the nuts loose at this time.

Step 10: Attach The Front Mounting Bracket To The Car

Raise the front end of the leap and bracket assembly into place and install the three bolts.

Make sure the parking brake cablevision is below the leap, and elevator the forepart of the spring and the bracket into position. In that location is a tab on the bracket that must slide into a corresponding hole in the body. Loosely install the mounting-bracket bolts.

Stride 11: Install The Spring Plate And Buffer Pad(s)

It's of import to marshal the rubber cushions properly when reinstalling them.

If your car was designed with jump cushions, they only fit 1 way. The pads must line upward and fit the spring and plate properly. In that location is also a pigsty in the spring plate that the bolt going through the springs fits into.

Locate the ribs on the absorber and the upper bound mounting plate. Install the upper cushion so these line up. Install the lower cushion pad with the spring locator dowel pivot. Position the spring plate and then the dowel pin and holes line upward. Loosely install the nuts and bolts.

Step 12: Reattach The Stupor Absorber

Slide the daze into place and loosely install the hardware. Also move the parking brake cable into place and secure information technology.

Left: It'south easiest to install the shock into the lower mount first. Recall to place a washer and so a bushing over the lower stud prior to installation. Correct: Installing the upper shock mounting bolts.

Step xiii: Tighten Everything

The final stride is to tighten everything. This ways both upper and lower shackle bolts, the four nuts on the lower spring plate/daze mount, and the three bolts on the front spring subclass/pocket.

Take care when putting things back together. Incorrect reassembly can crusade a big problem.

Recollect, always clothing rubber glasses whenever working under your automobile. Rust and dirt accept a manner of finding their way into your eyes.

Source: https://www.chevyhardcore.com/tech-stories/remove-and-replace-leaf-springs-like-a-pro/

0 Response to "How To Remove Rear Springs"

Post a Comment